Scaling UMI: Labor, Hardware, and Utilization

~80% of Universal Manipulation Interface (UMI) gloves sit idle at any given time.

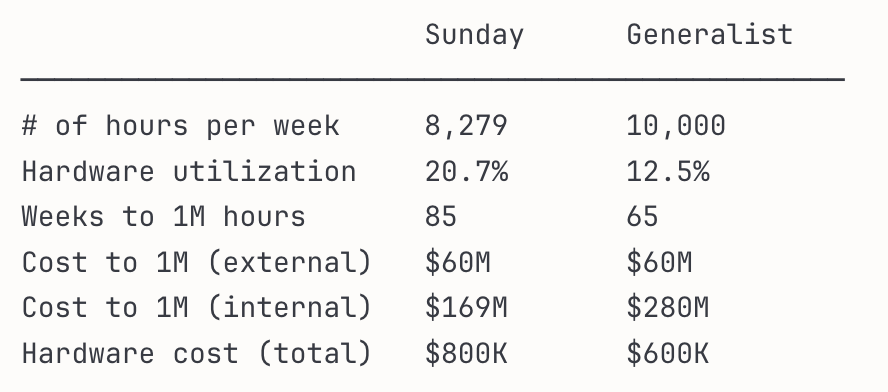

I dug into two robotics labs using universal manipulation interfaces (Generalist, Sunday Robotics) to learn more about how they operationalize data collection.

Everyone focuses on scaling operators, hardware, and cheaper manufacturing. But utilization—the % of hours a glove produces useful data for training—is the next logical lever, and I wanted to quantify where both companies stand.

Key Findings

I looked through each company’s technical blogs, graphs, and job listings (with some educated guesses) to build a rough model.

My findings:

- Sunday’s hardware utilization is higher (~20% vs ~13%)

- Generalist collects more data per week (~10k hrs vs my estimate of Sunday’s ~8k)

- In the near term, labor dominates hardware costs (>95% of total data spend).

Scaling labor & hardware is necessary, not sufficient

Both companies will pour capital into similar playbooks: external collection firms (like @scale_AI, @micro1_ai, and @instawork, etc), customer data-sharing deals (free data collection agreements), building in-house teams, and Chinese manufacturing for cheap UMIs. All of these methods scale directly with capital—the more you spend, the more data you get.

The differentiator becomes efficiency: how much useful data each glove-hour actually yields. At 10% utilization, 90% of your in-house labor spend is waste. Better utilization also means higher data collection throughput.

Low utilization signals the difficulty of scaling into new environments. It means more logistical overhead and more idle time.

One of the main advantages of using an external labor force is that you force them to absorb the costs of inefficiencies. Either they don’t pay workers during downtime, or take a hit on margins. Labs are paying for the data, not the service.

Improving utilization

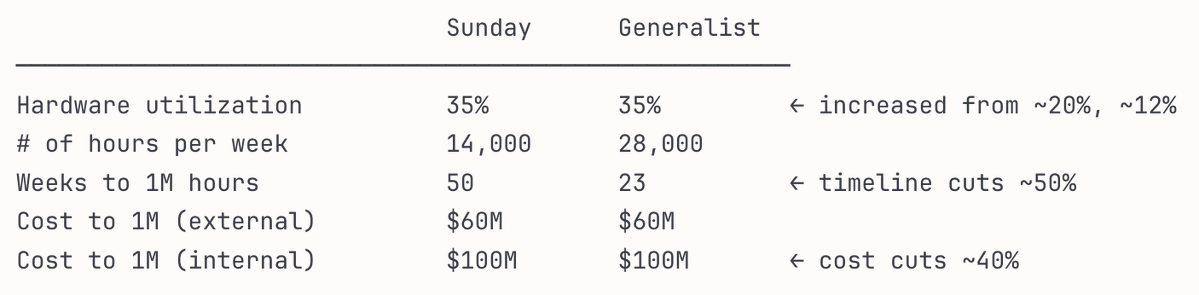

I modeled a simple scenario: if utilization rises to 35%, in-house collection costs and timelines drop by about 50%. Achieving the same acceleration by other means would require doubling both labor and upfront hardware spending.

But unlike scaling up headcount or equipment, boosting utilization is highly attainable—improvements to operator software, better distribution and logistics, faster shipping/handling, and better training for “in-distribution” demonstration can all move the needle.

Taken together, higher utilization could actually make in-house teams price-competitive with external vendors, while also offering the advantage of a much tighter feedback loop between data collection and research.

The UMI flywheel

The UMI flywheel kicks off once base models are at a level of performance where widespread deployment is feasible and customer fine-tuning can handle “last-mile delivery”. I predict somewhere around 1 million hours.

Whichever organization hits this first will start the flywheel, distributing low-cost gloves to end-consumers, gathering free and cheap data, and improving base models in a self-reinforcing loop.

Success will come down to which organization can execute on the levers of scaling labor/hardware while simultaneously increasing the efficiency of existing resources.

Model details

Spreadsheet: UMI Utilization Model

- Some results are highly sensitive to estimates (such as average episode length)

- Feedback on assumptions or modeling approach is welcome!